How we process raw materials to produce food ingredients has an impact on sustainability of the final food product. How much of the raw material are we using? Are we able to use the side-streams? Are we creating waste? These questions are even more important today as researchers and companies work towards realizing the United Nations Sustainable Development goals and creating a sustainable food system. In this article, Dr Yang and Dr Nikiforidis of Wageningen University describe recent advances aimed at producing proteins and oil-bodies called oleosomes with mild processing techniques.

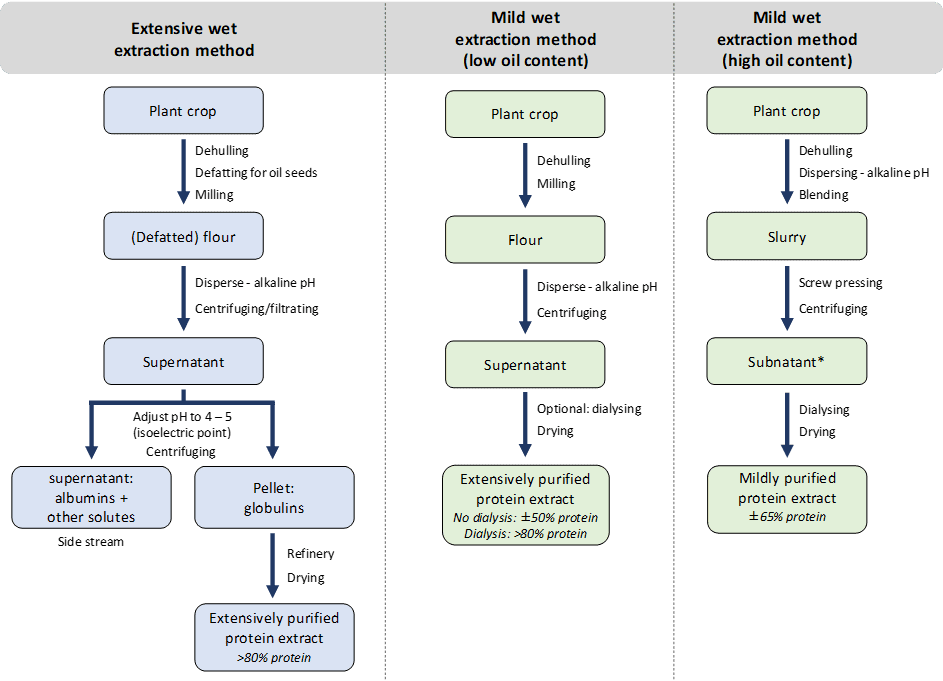

Plant proteins are crucial in producing sustainable and healthy food products. First, proteins are extracted from the plant crops, which are generally performed with an intensive/extensive process due to many process steps and the requirement of copious resources, leading to high-purity protein ingredients (overview of the process in Fig. 1). Additionally, there are indications that intensive processing reduces the performance of plant proteins in foods, e.g. creating foams, emulsions and gels. A more sustainable solution could be mild purification processes (example of a mild process in Fig 1.). More simple processes with fewer process steps also result in plant proteins with higher performance in, for instance, foaming, emulsifying and gelation1,2.

Figure 1. Schematic overview of extensive and mild extraction methods.

Slight difficulty in mild purification is the low protein concentrations, typically between 50 – 80%. Fewer process steps could result in the presence of non-protein components, such as phenols and lipids. Phenols are known to induce bitter and astringent off-flavours and aggregation of proteins, leading to lower protein solubility and performance. Therefore, the presence and type of phenol should always be carefully assessed, and removed or inactivated by, for instance, dialysis or the addition of anti-oxidants. Another non-protein component in mildly purified protein extracts is lipids. In our mild extraction method, the lipids are retained in their original/natural structure (oleosomes). These natural lipids are highly stable, and can even remain in plant protein foams without interfering with the protein performance under specific conditions8. In short, the impurities after mild protein extraction can be present without harming the techno-functional properties of the proteins.

Another novel development is the control of the protein composition using protein extraction methods. Plant crops have several classes of proteins; classified based on their solubility. Commonly utilized plant crops are soybean and pea, which are high in globulins (soluble in salt solutions) and albumins (soluble in water). The extensive protein extraction method mainly focuses on the isolation of globulins, while albumins are often discarded. Nowadays, there is a convincing indication that the albumins possess promising functional properties, such as foam and emulsion stabilization. Albumins could be an overlooked protein fraction, which should definitely receive more attention from academia and industry.

Additionally, albumins can also be included by mild extraction, as albumins and globulins are co-extracted. Leading to an outstanding performance in foaming, emulsifying and gelling properties. On the other hand, globulins seem to have a higher performance in stabilising oil droplets than albumins. These findings suggest protein composition-dependent functionality; this protein composition can be altered by the protein extraction method. As a result, the protein extraction method can be used to perform targeted fractionation, leading to globulin-rich extracts (high purity, emulsion stabilisation), albumin-rich extracts (foam stabilisation), and albumin-globulin mixed extracts (high solubility, emulsion & foam stabilisation, stiff gel formation).

In summary, mild purification of plant proteins is a huge step toward more sustainable ingredients. At the same time, such methods are suitable to control the techno-functional properties of the proteins. Exploring mildly and sustainable plant-based protein ingredients is novel and exciting; and a vital step in obtaining ‘good’ proteins to create healthily and tasty food products.

Authors : Dr. Jack Yang & Dr. Costas Nikiforidis, Department of Agrotechnology and Food Sciences, University of Wageningen, The Netherlands

References:

(1) Yang, J.; Faber, I.; Berton-Carabin, C. C.; Nikiforidis, C. V.; van der Linden, E.; Sagis, L. M. C. Foams and Air-Water Interfaces Stabilised by Mildly Purified Rapeseed Proteins after Defatting. Food Hydrocoll. 2020, 112, 106270. https://doi.org/10.1016/j.foodhyd.2020.106270.

(2) Yang, J.; Berton-Carabin, C. C.; Nikiforidis, C. V.; van der Linden, E.; Sagis, L. M. C. Competition of Rapeseed Proteins and Oleosomes for the Air-Water Interface and Its Effect on the Foaming Properties of Protein-Oleosome Mixtures. Food Hydrocoll. 2021, 122, 107078. https://doi.org/10.1016/j.foodhyd.2021.107078.