Many new technologies are being investigated to see whether they can be applied to plant-based foods. 3D printing offers a range of possibilities for creating texture or shape in foods, and could be applied to print protein-based foods such as meat or fish alternatives. In this article, Professor Makoto Takemasa of the Life Sciences and Engineering Department,

Graduate School of Science and Engineering, Tokyo Denki University, describes his work using soy protein as a “printing ink” for plant-based foods.

The world’s population is predicted to surpass 9 billion by 2050. Thus, increasing attention is being paid to the world’s ability to secure sufficient food to sustain this population.

Solutions that are implemented by or are close to the final consumer include efforts to minimize food waste, extend food expiration dates, and reduce food loss. Therefore we expect that the ability to use only “necessary components” in the precise “amount needed” at the “right time” to assemble food in forms that are “easy to consume” will contribute greatly to the reduction of food waste.

The use of 3D printing technology to prepare and construct objects of various shapes and forms has advanced dramatically in recent years. Recent reports describe practical applications for this technology ranging from the manufacture of construction materials to the production of organs for use as models in surgical training. 3D food printers represent the application of this technology in the context of food.

Food printers offer three new possibilities. The first is the potential to prepare different ingredients as “food inks,” which can then be combined or shaped in various ways. For example, if carrot puree is used as “ink,” just the right amount of this vibrant orange ink can be “printed out.” Furthermore, food inks can be readily transported.

The second possibility is the potential to change the texture of foods at will; for example, converting something with a complex structure to a texture that is better suited for someone with swallowing difficulties (dysphagia). Research is being carried out to investigate the possibility of changing food texture by changing the viscosity of the food inks used as well as changing the size and shape of the finished product (e.g., cubes or spheres with cavities).

Fig.4. Soy Protein Research, Japan 22, 35-39, 2019.

The third possibility is the potential to create substitutes for existing foods. If 3D food printers can reproduce the color, shape, and flavor of foods such as tuna (which are at risk of depletion) and beef (the production of which has substantial environmental impacts), there is a good chance that these foods can be produced in a way that is environmentally friendly and sustainable.

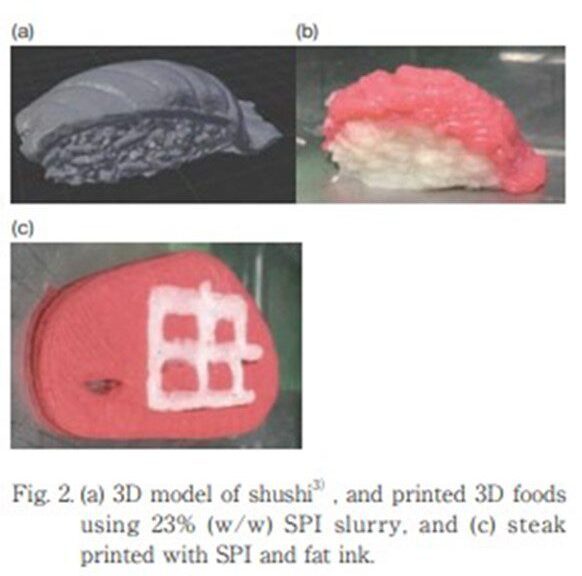

Fig.2. Soy Protein Research, Japan 23, 52-56, 2020.

We studied the possibility of using soy protein as a food ink as a means to relieve the protein crisis. The following comments were provided by the reviewers of this research.

① It is anticipated that promotion of plant-based resources, especially the use of soy protein, will be an effective means of achieving SDGs. The development of soybean products with a wider range of consistencies and textures than in traditional processed soybean products is expected to help promote soy protein use worldwide. This research uses a 3D printer to create processed foods made with soy protein that have a wide range of textures.

② 3-Dimensional (D) food printing is an advanced food processing technique, and we have expectations for its extensive application in health situations and food designed for an aging population. This study attempted to apply edible soy protein isolate (SPI) for the development of food ink materials of the 3D printing technique. The 3D modeling of SPI food by the printing approach would be highly acceptable when appropriate viscosity of the SPI ink is achieved during the process.

More details on the research are available in Japanese in the following reports. The abstracts are provided below in English:

Development of ‘Food Ink’ from Soy Protein Isolate for 3D Food Printing

Soy protein isolate (SPI) was used to develop edible paste ink as ‘Food Ink’ for food 3D printing. Aqueous solutions of soybean protein were prepared at various concentrations ranging from 5 to 50%. In all the concentrations, extrusion from the syringe was possible, but the quality of the printed object was relatively low compared with the other food inks, probably due to the viscoelastic properties of aqueous suspensions of SPI alone. Xanthan, a microbial polysaccharide used in food industry as a thickener, was added to improve the viscoelastic properties to maintain the object shape. The food ink developed in this study was relatively more precise than other food inks. Soy Protein Research, Japan 22, 35-39, 2019

https://www.fujifoundation.or.jp/search/pdf/040/40_07.pdf

Food Ink Development of Soy Protein Isolate for Food 3D Printing

Soy protein isolate (SPI) was used to develop edible paste ink as a ʻFood Inkʼ, especially as protein ink for food 3D printing. Aqueous dispersion of soybean protein was prepared at various concentrations ranging from 15 to 30% to print 3D objects containing relatively high protein concentrations comparable to real meats, such as beef, pork, and chicken. Protein energy malnutrition (PEM) is often found in the elderly, and food containing a relatively large amount of protein is probably useful for them. After some improvements in both the food ink and paste extruder, SPI slurry-based food ink at 25% (w/w) can be used to print 3D food objects. This protein content is higher than that of real meats, such as beef, pork, and chicken, which ranges from 15 to 23%. Using the above SPI-based food ink, we successfully printed a steak-shaped object using SPI ink and fat ink, and sushi using SPI and carbohydrate ink. Soy Protein Research, Japan 23, 52-56, 2020.

https://www.fujifoundation.or.jp/search/pdf/041/41_09.pdf