Developments in food technology enable us to better utilize the side streams from food production. Tofu is a traditional soy-based food, which results in the production of the fiber-rich okara as a waste product or side stream. Some okara can be utilized in dishes, such as okara simmered with vegetables and soy sauce seasoning or high-fiber cookies, but so far its use has been limited.

Prof. Takao Nagano of Ishikawa Prefectural University in Japan has been investigating the possibility of transforming okara into nano-fibers that can offer new and different functionalities in food. This report explains some of the work that he has done with the okara nanofibers.

Cellulose is a key component of plant cell walls, and it gives them their hardness and elasticity. Cellulose fiber can be reduced in size to the nanoscale through a process called nano-fibrillation and the products are then called nanocellulose (NC). In recent years, nanocellulose from plant materials such as wood has attracted attention because it is sustainable and can contribute to CO2 fixation. Nanocellulose is characterized by its high strength (about five times that of steel), high elasticity and light weight (about one-fifth that of steel), and high dispersibility and viscosity.

Miniaturization is the key technology for the procedure of nanofibers. As cellulose is fibrous, it must be mechanically crushed and sheared. Often a wet grinder (WG) device that disperses the material in water to produce fine particles is used. The WG system (Fig. 1) is less able than a water jet system (WJ) to produce small particulate matter, but it is also used in food manufacturing and processing because it is a millstone-type system that does not get easily clogged up by the test material.

Fig.1 Nano-fiber generator (Water-Grind type, Masuko Sangyo Co. LTD.)

Okara (soybean curd residue) is a byproduct of tofu and soy milk production. Although okara is rich in dietary fiber, which is mainly cellulose, it is rarely used as a food. Therefore various studies have been conducted to improve its physicochemical properties in order to expand its use. Nagano et al. improved the physical properties of okara using a WG apparatus and examined how addition of nanocellulose impacted the gelling properties of soy protein.

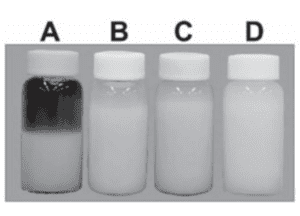

A Super masscolloider (MKCA6-2, Masuko Sangyo Co., LTD) was used as the WG device, and the number of WG treatments was varied to produce fine particles of okara in solution (2 wt%). Fig. 2).

Fig.2 Wet-type grinder (WG)-treated okara in water after 24h. Okara (2 wt%) was treated with the WG for different passages. (A) untreated; (B) one passage; (B) three passages; (D) five passages.

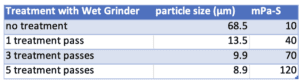

Table. 1 Analysis of particle size distribution (size in μm) and the viscosities of the slurry (mPa-S) under different treatment conditions.

The impact of the different WG treatments on gel properties were investigated by mixing th various nanocellulose bean curd solutions with soy protein. The results in a 1% NaCl shown in Fig. 3. These results indicate that the process of bean curd nano-fibrillation strongly affects the gelling ability of soy protein.

Fig.3 The breaking stress and strain of 6% soybean protein isolate (SPI) gels to which 1% wet-type grinder (WG)-treated okara was added after different passages at 1.0% sodium chloride concentration. Different letters indicated significant differences (p<0.01).

Soy protein is widely used in processed meat products, frozen foods, chilled side dishes, and health foods that require its gel-forming functionality. This gel-forming ability is used to improve the texture of products such as deep-fried kamaboko( a fish paste product similar to crabsticks). This study showed that nanofibrillation could be applied to improve the physical properties of okara, and when mixed with soy protein this then has a significant impact on the gelling properties of the resulting food. As new foods are developed, we expect that nanofiber-treated okara can play an increasingly important role in modifying the physical properties of the resulting foods.

You can find the original article by Prof Nagano (in Japanese) at the following link: